Metal-Plasma Srl has been specializing in protective coatings on mechanical components for over 30 years.

MP’s products and services are applied with the aim of giving the components a high degree of efficiency, while keeping the basic construction material unaltered.

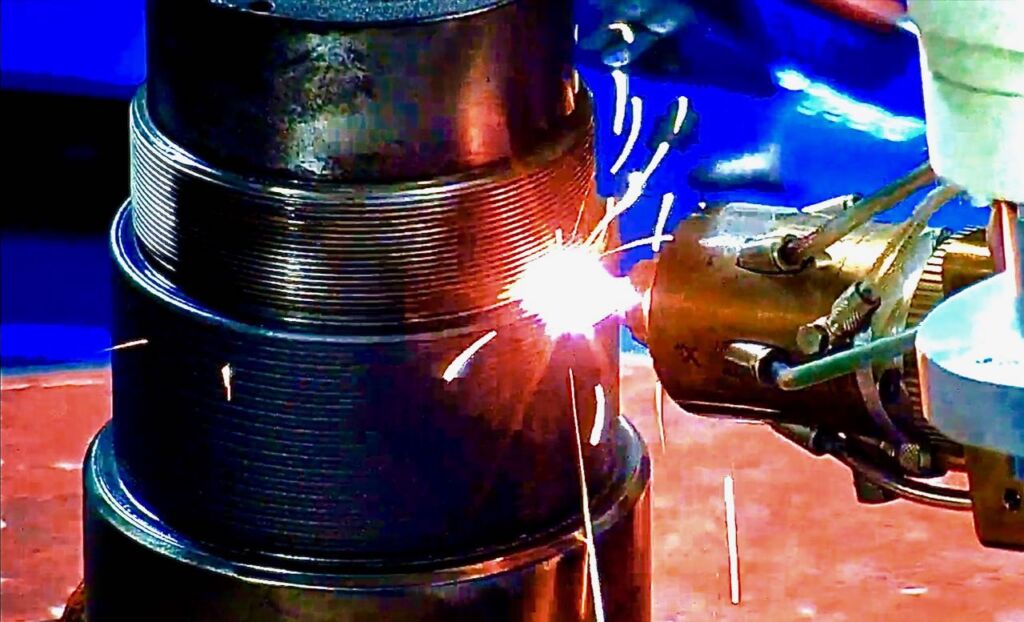

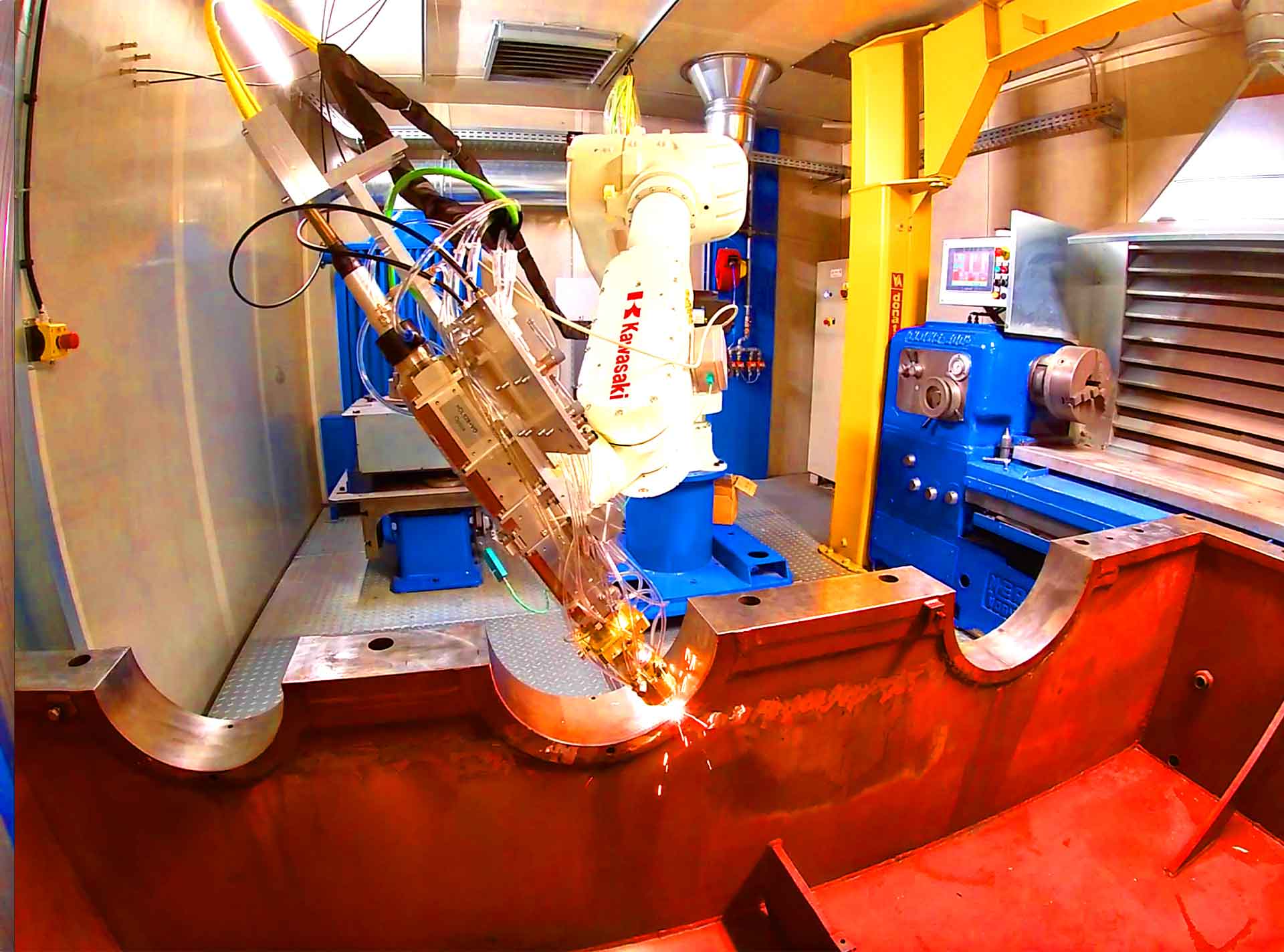

Thanks to our advanced coating technologies such as: Laser cladding, Hvof, Aps, Wire gas spray, we can create coatings made of a very wide range of materials based on Ceramics, Carbides and Super metal alloys, chosen on the basis of the technical needs necessary to overcome the problems of: wear, corrosion, thermal and electrical insulation, an increase or a decrease in friction or dimensional restoration of worn areas.

Metal-Plasma specializes in various application sectors such as iron and steel sector, packaging, gas & oil, automotive, paper, etc. and offers complete manufacturing solutions on various components such as: hydraulic cylinders, rollers, shafts, spindles, bushes, rings, blades, vanes and many others.

Our coatings can also be applied to components of different geometries and materials, with dimensions up to:

6 m long X 2 m in diameter with a weight up to 5000 kgs.

HOW?

- Reduction of friction coefficients, reducing power losses due to it;

- Increase in thermal efficiency;

- Possibility of reducing the weight of the components by using lighter and more workable base materials such as aluminum and titanium, thus reducing the rotating masses and inertia;

- We regenerate worn components, so as to reduce the material to be demolished and disposed of;

- Longer life of components and lower maintenance and downtime costs.

Sustainable mechanical components

we improve the eco-sustainability of your plants and components

Our coating technologies help reduce environmental impact by increasing the effectiveness and efficiency of the mechanical components treated.