SOLUTIONS FOR MOTORSPORT

Metal-Plasma Srl has been collaborating for several years with Formula 1 Teams and Teams present in the world championship such as Gresini, and it also collaborates with international-level exhaust manufacturers.

It is a source of pride and above all of motivation for us to contribute to the improvement of the technical performance of motorcycles thanks to our ceramic coatings on the collectors and not only that.

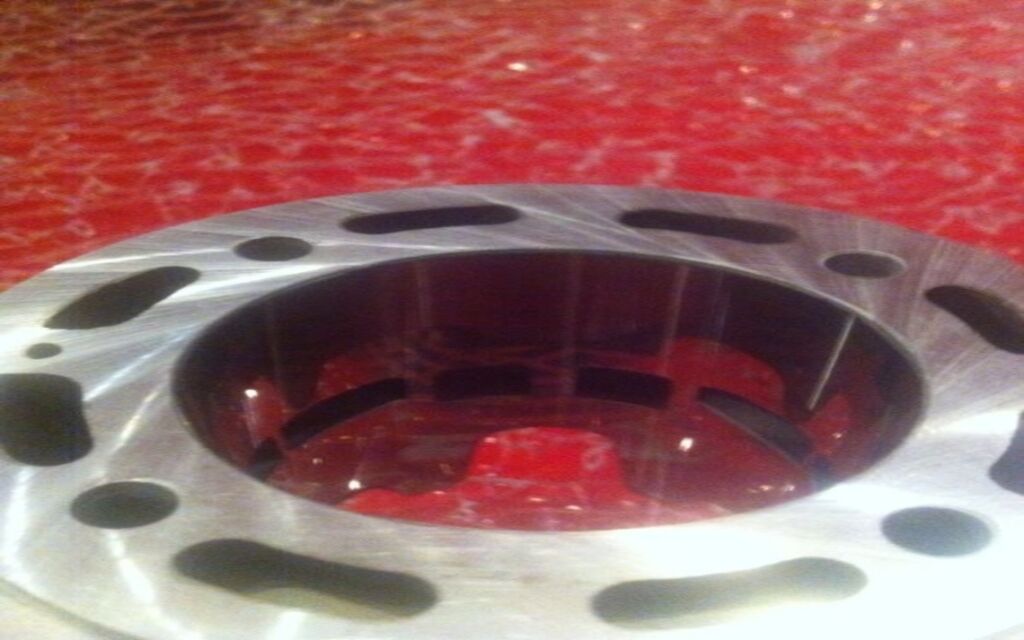

COATINGS FOR MECHANICAL COMPONENTS FOR THE MOTORSPORT SECTOR

We also do coatings for the automotive, motorcycle, kart, scooter sectors, carrying out treatments for collectors, turbines, pistons, crankshafts, braking systems, CVT transmissions and much more.

RESEARCH AND DEVELOPMENT

Metal-Plasma operates in a very dynamic and fluid context which, in recent years, has been affected by a positive economic situation: in fact, more and more post-production surface treatments are required for a wide range of applications that require improving both the mechanical properties of the components and the levels of finishing.

In order to be able to continue to guarantee levels of the highest quality and to expand the potential applications of deposit and coating processes, the company has decided to invest in numerous research and development activities, aimed in particular at the validation of new processes of production, the use of new materials for special applications and the use of traditional technologies for new applications. These activities are characterized by numerous very significant elements of innovation and differentiation.

In particular, the projects are characterized by having the following peculiarities: CREATIVITY, REPRODUCIBILITY, SYSTEMATICITY, RISK AND UNCERTAINTY. Metal-Plasma is characterized by a continuous search for solutions to problems and requests, from which projects are born for which research and experimental development can be initiated. This year the projects considered can be classified into 4 categories:

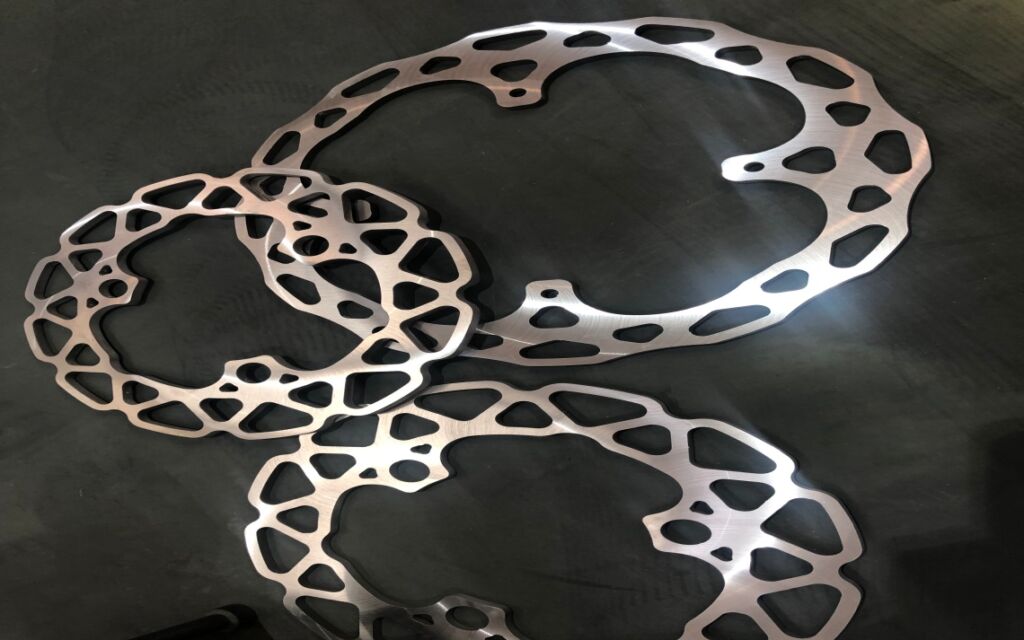

- improvement of brake discs for the world of bicycles;

- deposition on the finished piece for dimensional restoration of the components;

- characterization of the Laser Cladding process;

- deposition of coatings for polymeric components.